Background

The company is a Chinese cross-border e-commerce enterprise, primarily selling through platforms such as Amazon.

Challenges

With the rapid increase in daily order volumes, the company has encountered numerous challenges in its actual business operations that are difficult to resolve through traditional means:

- Lack of standardized management processes: The overall team is relatively young and lacks management experience, especially in the procurement and warehouse management modules, where standardized management processes are absent.

- Existing software struggles to meet personalized needs: The ERP systems in the cross-border e-commerce sector have fixed process settings that cannot accommodate the company’s need for personalized customization.

- Severe data silos: The company has more than ten operational teams internally, with departments operating independently. Different business modules even use different ERP products, resulting in data that cannot be interconnected between departments.

Value

- The first application was implemented within 2 days, and the entire system was delivered within 1 month.

- Business SOPs were developed and systematized for workflow.

- The system’s performance was quickly and flexibly adjusted according to business and product needs, rapidly meeting business demands.

- Multiple application systems were realized through a no-code/low-code platform, with data naturally interconnected.

Core Application Scenarios

Warehouse Management

As the company’s raw materials purchased in the early stages need to be assembled first, then stored as finished products before shipping, it was necessary to build related applications for raw material inventory management, assembly production management, and finished product inventory management. Traditional ERPs cannot quickly expand to support such scenarios, and custom development is costly, in addition to needing to be compatible with some of the company’s inherent business logic. With the rapid expansion of business, warehouse operations have become busy, and many products cannot follow the processes set by the ERP software while ensuring timely delivery.

The system we built not only supports flexible customization of processes for different business lines but also allows for special processes to be expedited, meeting the diverse needs of the company’s rapid business development.

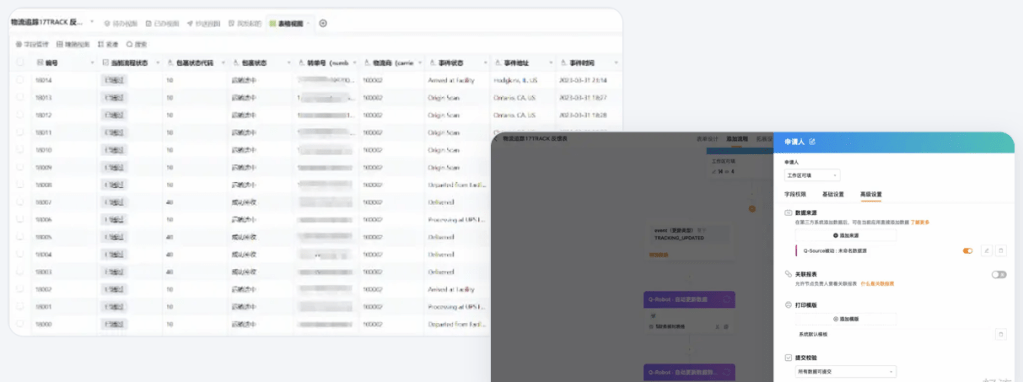

Logistics Management

After finished products are stored in the warehouse awaiting shipment, they need to be sent to Amazon’s overseas warehouses, which then deliver the goods to different overseas customers. Previously, orders from different departments to different overseas warehouses required manual identification and operation, which was time-consuming and labor-intensive. Now, the system can automatically integrate information such as the weight distribution of goods, maximizing resource utilization before sending to logistics companies, not only saving the cost of manual calculation but also significantly reducing express delivery costs.

Additionally, the system has integrated the query interface of logistics companies, enabling dynamic real-time tracking of logistics status.