Background

The company is a surface coatings manufacturer with over 90 years of history, operating multiple production bases and R&D centers worldwide. Its products are widely used in various fields, such as building facades, system doors and windows, automotive wheels, furniture, home appliances, and machinery.

Challenges

The company embarked on its digital transformation journey early on, adopting third-party SaaS products and developing some systems in-house through its own R&D team.

To further improve service quality, the company decided to develop a service evaluation system, with some modules outsourced to a third-party development team. Since the company had its own development team, initial communication and delivery proceeded smoothly, and the system was delivered within a month. However, after the system went live, users identified several unreasonable functionalities that needed adjustments. The third-party developer cited excessive code changes due to requirement modifications and requested additional budget (similar to the initial cost) and another month to complete the changes. Both the timeline and cost were unacceptable to the company.

After careful reflection, the company identified two major pain points at its current stage (common issues in the industry):

- Lack of thorough business requirement analysis, leading to frequent requirement changes and time-consuming mid-project adjustments.

- Over-reliance on third-party developers. High-end service providers are expensive, while smaller developers, though initially cost-effective, incur escalating maintenance costs, with every change requiring additional expenses.

After screening and comparison, the company ultimately chose our no-code development platform, achieving excellent results.

Value

During the initial implementation, the company completed the construction and optimization of the evaluation application in just over half a month, including mobile push functionality, validating its value.

Subsequently, the company built multiple application scenarios, including quality management, technical service management, production management, TPM management, supply chain management, and logistics delivery systems. Currently, our solution has become a crucial part of the company’s daily operations, forming a robust digital support system alongside SAP and in-house product management software.

Core Application Scenarios

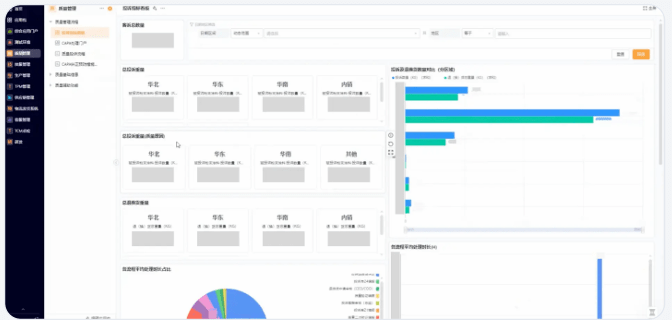

Quality Management: Customer Complaint Process & CAPA

For customer complaint collection, the company established a dedicated customer complaint/technical service portal. Sales and distributors (accessing the system as external users for collaboration) can quickly initiate applications through shortcut buttons in the portal.

Once submitted, applications are automatically processed according to the system’s standardized workflow. Relevant data is automatically stored in the system backend and synchronized to related reports, clearly presenting key complaint indicators for managers to quickly identify critical issues.

After handling complaints, the responsible department must address the quality issues, known as CAPA (Corrective and Preventive Actions).

Previously, without a system for management, CAPA tasks often fell through the cracks. During accountability meetings, responsible parties frequently cited reasons like “too much time has passed” or “too many emails to notice,” leading to delays. The quality department also struggled with KPI tracking.

With data consolidated in the system, the company can now use the “CAPA Processing Portal” to make improvement tasks clear for each department and individual, significantly increasing CAPA closure rates.

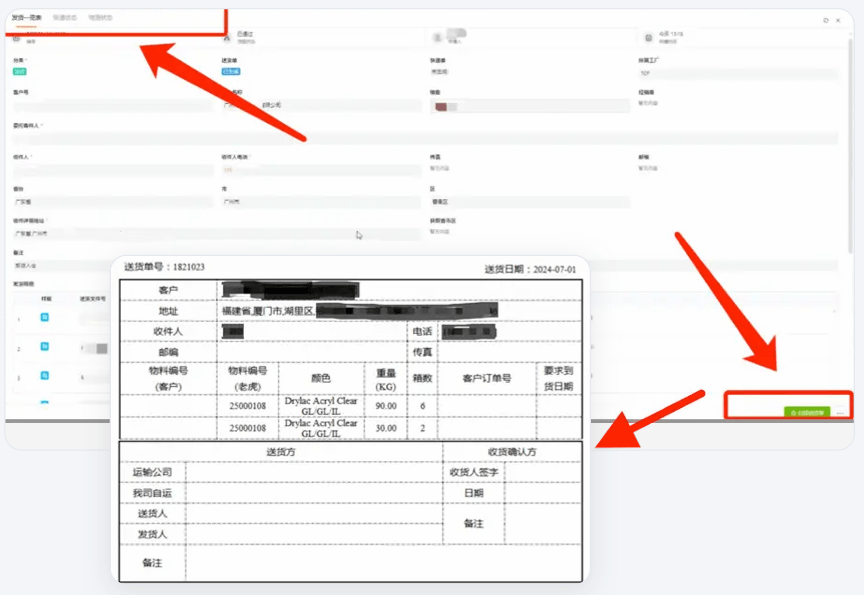

Logistics: System Integration & Freight Calculation

Later, the company optimized its logistics delivery system through our platform. By integrating interfaces with multiple local logistics companies, the system enabled online order placement, printing, status tracking, and reconciliation. All sales or other entrusted shippers can now track their customer order statuses through the system.

The company integrated data from delivery notes, shipping notes, and courier documents, allowing quick access and one-click printing in the “Delivery Overview.”

Different transportation methods have varying billing methods. By integrating with map service providers, the system automatically retrieves geographic information and calculates freight costs using corresponding algorithms. During reconciliation, these costs can be directly compared with logistics/courier fees.

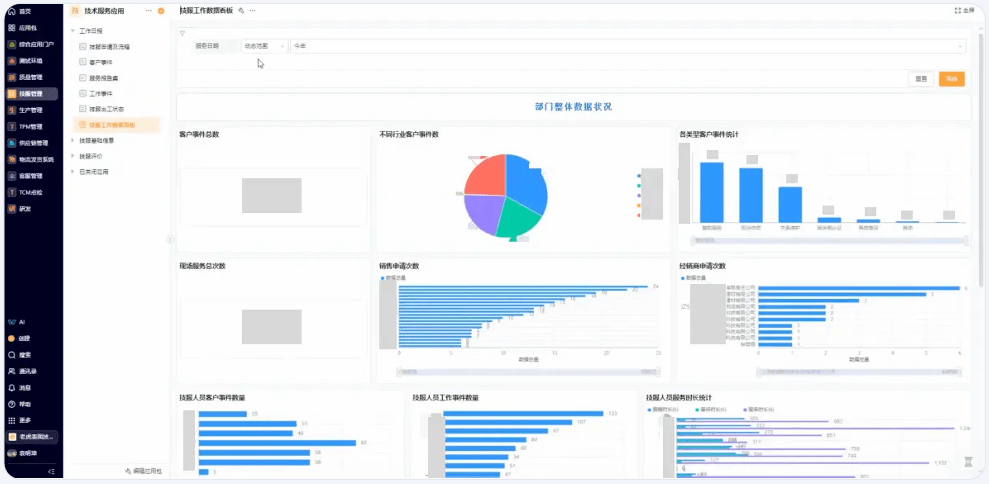

Technical Services: Work Records & Data Analysis

To effectively manage employee work, technical service colleagues must provide detailed service reports for each task.

Previously, the technical service department recorded work in Excel and wrote service reports in Word, which were then uploaded to the company’s cloud drive. This process was cumbersome for employees and time-consuming for statistical aggregation and review.

Now, employees use the system for recording, enabling work log entry, report generation, and personal work data tracking, significantly improving technical service efficiency.

Additionally, the company built a “Technical Service Work Data Dashboard” for managers, providing a clear overview of the department’s annual work.

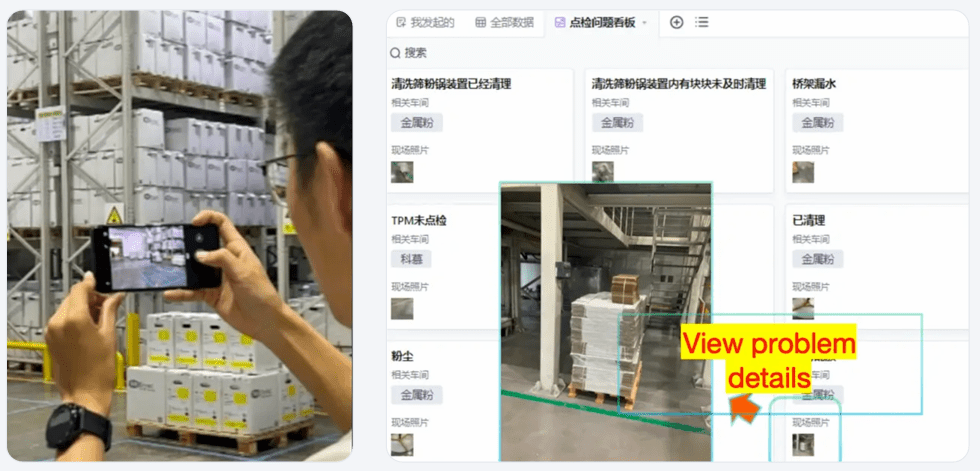

Routine Inspections: Inspection Reminders & Issue Tracking

Daily operations in the company’s production, supply chain management, and other departments involve routine inspections.

Previously, the company used paper-based inspections, leading to missed inspections, delayed issue reporting, and unresolved feedback.

Now, the system periodically assigns inspection tasks to staff, who can complete inspections via mobile photos.

Identified issues are automatically synchronized to the “Inspection Issue Dashboard,” enabling closed-loop on-site management for issue reporting and resolution feedback.