Background

The case study company is a global leader in the manufacturing of construction and mining equipment, diesel and natural gas engines, industrial turbines, and diesel-electric locomotives.

Challenges

Initially, the company relied on outsourcing development or using large platform products for digital management. However, during implementation, it became evident that each factory had different management logics and details, making it difficult for a single platform to fully meet the company’s management needs.

In terms of system integration, the company faced two main challenges:

- Multiple Business Systems: Employees had to use different accounts and passwords to log in to various systems, resulting in cumbersome operations and significant security risks.

- Andon Project Limitations: The Andon project only provided software notifications without hardware integration, making it difficult for engineers to quickly locate abnormal production line stations.

Value

- Unified Identity Authentication: Enabled single sign-on across multiple systems, reducing password fatigue and improving security.

- Quick Response to Production Incidents: Automated linkage of all production line equipment for rapid incident response.

- Rapid Deployment of Core Modules: Completed the deployment of four core modules across five factories within four months.

- Internal Digital Talent Development: Empowered the company to take the lead in system design and logic.

Core Application Scenarios

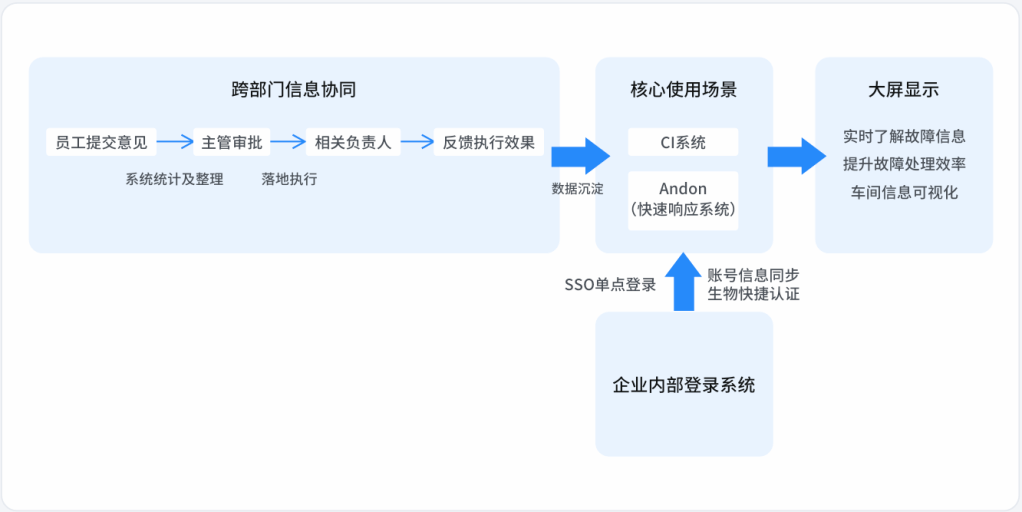

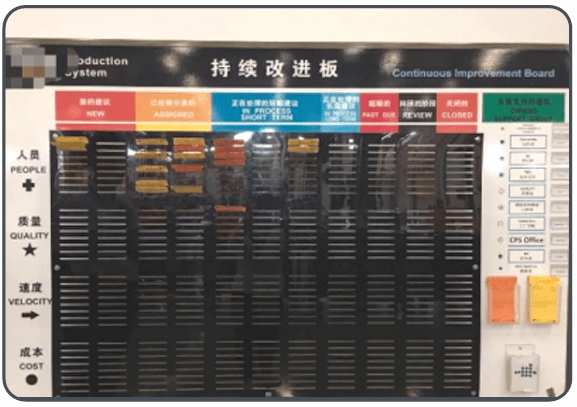

CI (Continuous Improvement – Rationalization Suggestions)

Through a systematic solution, employees can submit suggestions for various types of issues (safety, personnel, quality, etc.) anytime, anywhere. The system automatically categorizes and compiles these suggestions by department and issue type.

Once a rationalization suggestion is approved by a supervisor, the system automatically pushes it to the relevant responsible person for implementation, ensuring that no valuable employee suggestion is overlooked.

PAST

PRESENT

Compared with the traditional CI process of filling out paper CI cards, the entire digital CI process can be completed on the mobile terminal, which not only simplifies the process but also reduces waiting time

Andon (Rapid Response System)

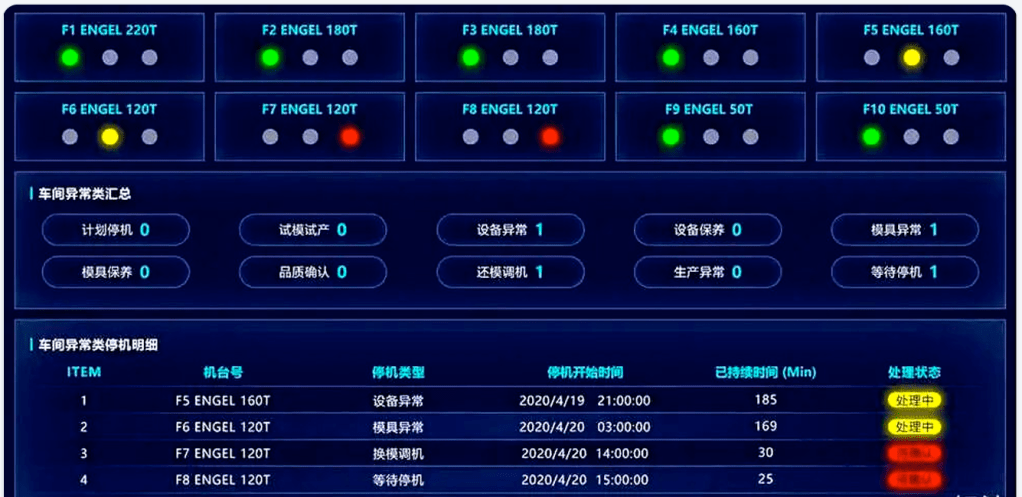

The company’s Andon project involves monitoring production line stations for abnormalities by binding hardware to station information.

PAST

- Slow information transmission, leading to delayed fault response.

- Unplanned downtime was not recorded, making cost accounting impossible.

- Real-time production status monitoring was unavailable.

PRESENT

- By accepting system requests, the specified workstation information and parameter data for controlling lighting are sent to the IoT hub, and the workstation status is displayed by lamps

Staffs can directly access the Andon application through the mobile phone, select the urgency and describe the problem, and then submit the report information:

Fault information is automatically notified to the supervisor for processing:

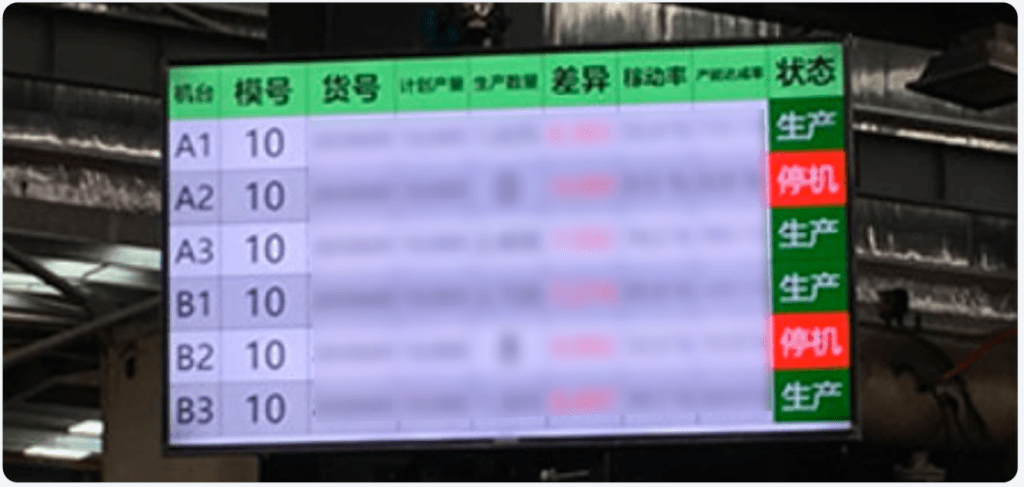

Factory large screen displays fault information in real time:

Improve fault handling efficiency:

Through online instant notification, maintenance personnel can be notified immediately after the fault information is submitted, eliminating the time for problem distribution and finding handlers

Real-time analysis of production data:

Comprehensive process operation, equipment status, quality problems and other process data are statistically analyzed and reports are generated, and the real-time collected on-site production status data is processed, stored and managed to provide a basis for production management analysis and subsequent continuous improvement.

System Integration

PAST

- During the project introduction period, account opening and registration were complicated

- Users often forget their account passwords when using the system

- Login authentication security levels are not uniform

PRESENT

- The system is perfectly integrated with the company’s unified authentication service. Both PC and mobile terminals can jump to the unified authentication login service page for authorization and authentication

This solution system is connected to the unified authentication service through the SSO single sign-on function, including enterprise organizational structure and personnel account information synchronization, authentication login, and supports mobile terminal faceID, fingerprint and other login methods. The deep integration meets the needs of deep integration of enterprises.