Background

The company is a European manufacturing company that mainly provides air hoods and ventilation systems and drying equipment for large paper machines for the papermaking industry.

Challenges

Faced with the rapid development of the business, the company has long defined the direction and positioning of digital production management, that is, to coordinate the company’s logistics, capital flow, and information flow to achieve a “three-in-one” digital strategy.

- Logistics: refers to the purchase application of raw materials (including contract & delivery order management in the process)

- Capital flow: refers to financial management (including payment application, etc.)

- Information flow: refers to the information flow of commodity inventory

In the past, the management of logistics, capital flow, and information flow was achieved through paper and Excel, resulting in bloated business processes and many inefficient transmission processes.

Value

- Complete 9 business modules and 26 core applications to meet the digital management of the core business scenarios of the enterprise, including: financial management, inventory management, project management, etc.;

- The overall operational efficiency of the enterprise (turnover rate, production rhythm, cycle, etc.) is improved, and the management enthusiasm of each position is effectively improved;

- Through the opening of the entire business process, collaborative office management is realized, project matrix management is promoted, and facts are fed back through data reports to help orderly sort out the progress, quality, cost, and authority of each link;

Core application scenarios

IMS

PAST

- Using paper or EXCEL records is easy to lose and leak data

PRESENT

- Raw materials and equipment information can be entered online, and inventory product numbers, quantities, and prices are automatically updated

- Through the QR code entry function, auxiliary applications such as QR code recognition packing lists in the material shipping link are added to realize material coding management, while increasing the matching degree between the underlying operation of entering and leaving the warehouse and the actual objects

Online Warehouse application

Real-time dashboard for warehouse in and out data

PDM

PAST

- When faced with the dilemma of a large number of orders, huge delivery pressure or insufficient procurement budget, if the design, procurement, production and sales processes fail to connect effectively, it is very easy to cause problems such as poor information flow and low communication efficiency between departments, which seriously affects the business process and restricts the growth of the enterprise

PRESENT

- Instantly and automatically associate data with multiple levels of approval flow, open up various links of logistics, capital flow and information flow, and realize the intensive and standardized main business process of “design-procurement-production-sales”, especially the drawing BOM decomposition, finance, purchase and sales in the “procurement-production” process. It can ensure the receipt of commodity invoices and the correspondence between warehouse in and out accounts, solve the problems of automatic update of accounts receivable, and greatly reduce the time spent on the circulation of each link

Warehouse process payment application process

Purchase data implementation dashboard

Collaborative office management

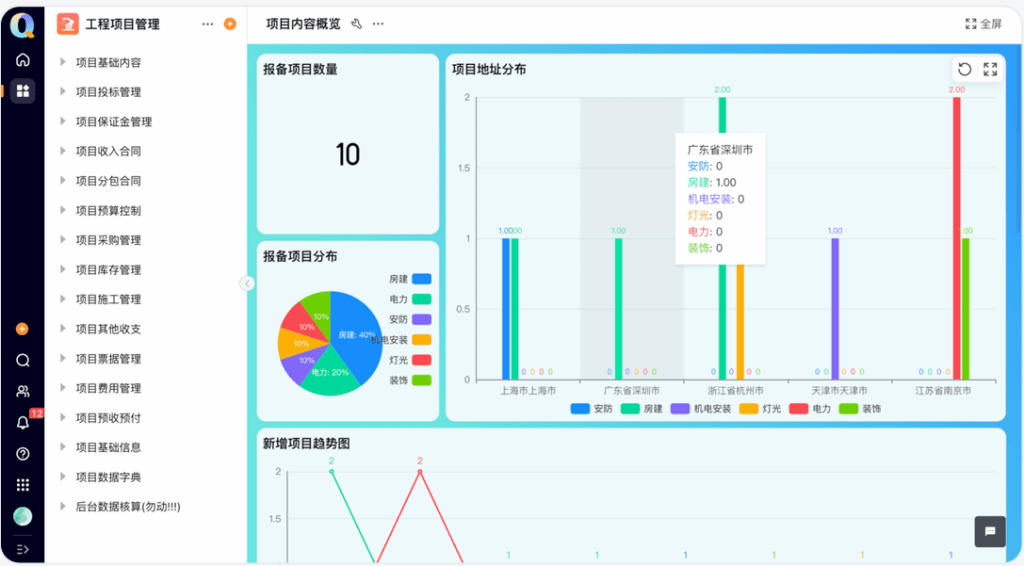

Through the opening of the entire business process, collaborative office management is realized and project matrix management is promoted. Real-time feedback through data reports helps to sort out the progress, quality, cost, and authority of each link in an orderly manner, ensure smooth internal and external communication, and guide business judgment with facts.

Take engineering projects as an example:

Realize online management of engineering projects, led by the engineering service department, and analyze and copy relevant reports and on-site pictures to marketing, design, and procurement for project site conditions, and transmit customer feedback information in real time during subsequent installation acceptance and quality assurance, so that on-site information can flow smoothly, improve the efficiency of each department in receiving product information perceived by end users, and promote the projectization of continuous improvement plans, answer calls, and improve platform communication efficiency

Engineering project management system: