Company background

The company is an expert in mobile hybrid energy (energy storage) solutions serving the world. It was founded in 2008 and is currently listed on the New Third Board. It is a company with a global layout.

Facing challenges

- Low Education Levels Among Frontline Workers

The majority of factory workers hold only junior high school diplomas, with very few having college or technical school qualifications. - Cross-Regional Approval Complexity

- Matrix Approval Structure in Group-Subsidiary Operations

Group executives often hold concurrent roles in subsidiaries, creating matrix-style approval chains that cross hierarchical boundaries. - The systems were isolated. Prior to the implementation of the new system, the six major systems operated in isolation and were not integrated.

- Low gross profit industries, with minimal IT investment and a pursuit of cost-effectiveness; Translate the above into English

- Industry characteristics, frequent process changes. If entering the new energy industry, customer demand and production mode are different from traditional products, and the process changes frequently;

- The increasingly strict regulatory and internal control requirements of listed companies have led to an increased emphasis on data security.

Effect value

- Codeless development can match the current situation of the company’s IT team, allowing IT personnel who previously did not know complex programming to undergo simple training and build all the business processes required for the group’s business.

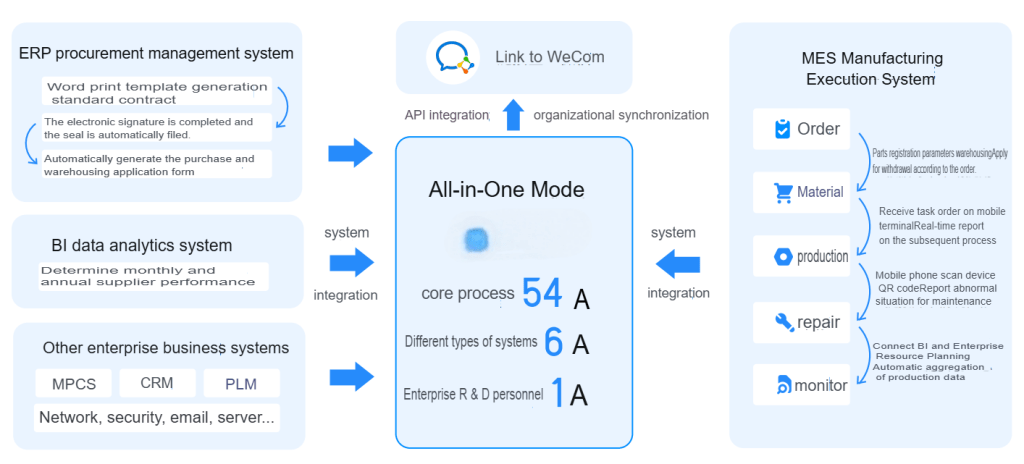

- The communication tool within the enterprise is Enterprise WeChat, and the integration of the system with Enterprise WeChat, especially the integration of organizational structure, eliminates the need for employees to install apps or receive additional training. New employees can use the system as long as they have enterprise WeChat, and their accounts will be cancelled immediately upon resignation.

- The various approval node settings built into the system fully meet the current development needs of the company, including matrix approval, and have powerful notification functions.

- The system has built-in flexible interface tools that can be integrated with the current six major systems of the enterprise. The rich API interfaces can be directly used.

Core application scenarios

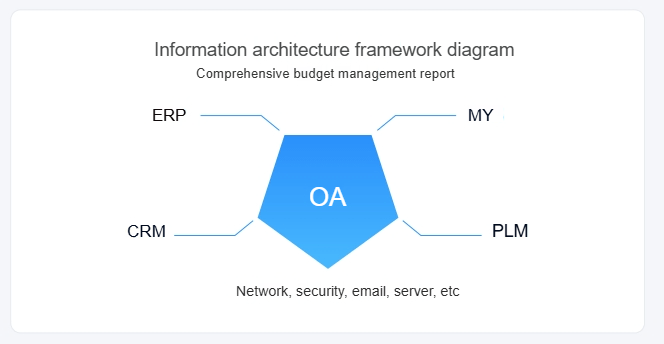

OA system

Approval is required across different locations of the company, but the language and approval system are completely different, with many approvers crossing over. Now, all cross departmental approval processes and data of enterprises are carried out in the built OA system. The approver always uses one interface, a simple interface, to solve all the problems encountered by department leaders during approval. At the same time, the system has a biggest advantage: it can complete approvals on mobile devices, and there is no need to bring a heavy computer for approval when traveling. At the same time, frontline employees only need to use one system for them.

Production management

| previously | The use of mobile devices in the system fills the gap of MES system. In the past, MES systems required program changes and deployment every time there was a process change, which was very time-consuming and labor-intensive. |

| now | Nowadays, the system is used to report production abnormalities, production start and completion, test bench information, equipment abnormalities, etc. User feedback shows that it is convenient to use and the interface is more intuitive. When it is necessary to modify the process, professional IT participation is not required. |

Taking production exception reporting as an example, frontline employees use their mobile phones to scan the unique QR code on the product through enterprise WeChat and directly report production exceptions. It supports taking photos and uploading, and the types of exceptions initiated by employees can be defined in the MES system. In addition, utilizing the powerful process engine of the system to assist Shoufan Power in identifying production anomalies, pushing them to MES and BI systems, and notifying the corresponding responsible persons to handle them. The production department holds regular meetings every Tuesday to review production anomalies that have occurred in the past week and determine responsibility. After processing, go directly to the initiator to confirm the processing results, and the production management personnel can see the abnormal information and processing status of each specific product.

Procurement Contract Management

The approval of procurement contracts has now been integrated with the new system and ERP system. After the purchaser completes the purchase order in ERP and approves it, the system automatically initiates a procurement contract review for the new system based on the defined annual contract supplier, company standard contract supplier, and counterparty contract supplier categories.

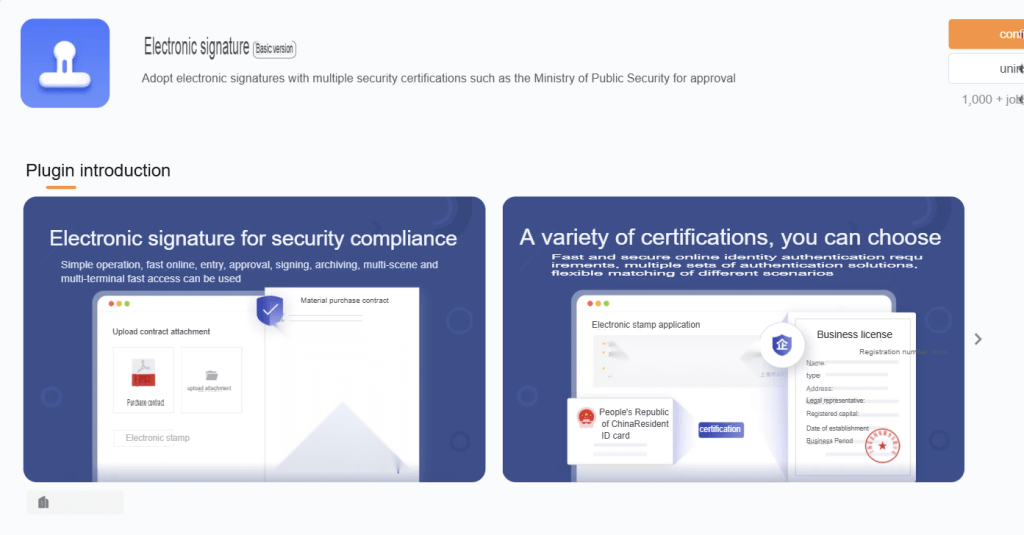

For suppliers with annual contracts or company standard contracts, a standard procurement contract in company format will be automatically generated without the need for anyone to sign. It can be directly integrated with the electronic signature function of the new system, stamped with an official seal, and converted into a PDF file for the supplier. The contract is automatically archived on the document server and set as read-only.

Procurement and warehouse management

After the purchaser completes the procurement and warehousing application form in the ERP system, the system automatically obtains information through the interface and checks whether the materials in the MES system are exempt from inspection. If they are exempt from inspection, the warehouse directly uses system 0A to count the quantity and check that the packaging is intact, and then notifies the ERP system to complete the procurement and warehousing. If inspection is required, after the warehouse quantity inspection is completed, it will be automatically sent to the corresponding incoming material inspector. According to the product sampling ratio and sampling specifications defined in MES, the system OA will automatically generate an inspection report. The inspector will check each item to confirm whether it is qualified, and directly take pictures of the unqualified products with their mobile phone. If it is unqualified and needs to be rectified by the supplier, the system will automatically attach the corresponding inspection report, initiate the VDCS process, and track the financial closed loop of this process.

All approval progress is visible in real-time in both the new system and MES system. The final data is sent to the BI system for determining the monthly and annual performance of suppliers (on-time delivery rate, quantity accuracy, and qualification rate).