Company background

The company is a wholly-owned Japanese enterprise mainly engaged in the cutting (laser/flame cutting), processing, and sales of steel plates. As a comprehensive steel trading company, the company will utilize all its operating resources to create maximum value for customers.

Facing challenges

- Inefficient Paper-Based Data Collection & Disorganized Workflow Management

- High-Cost In-House System Development

- Suboptimal Production Data Utilization

- Siloed Departmental Operations

Effect value

- Cloud-Based Recording & Real-Time Feedback

- Customizable Business System Configuration

- Real-Time Data Intelligence

- Visual Approval Process Automation

Core application scenarios

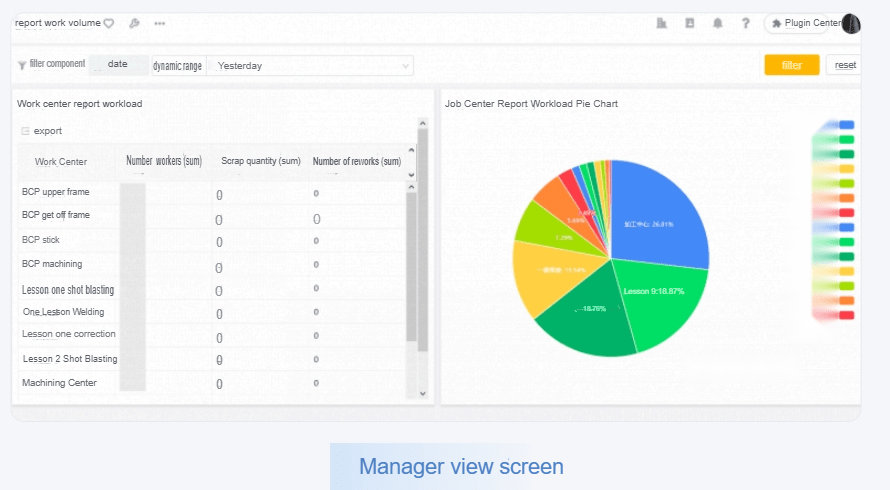

Production Reporting Management System

| formerly | Production department employees all use paper documents to collect data on product types, production quantities, etc. The reporting process is very cumbersome, and the data statistics are relatively complex, making it difficult to search and verify |

| now | By building a production reporting management system, it is convenient for employees to initiate reporting operations directly online, while achieving clear management of production data |

Meanwhile, enterprise managers can view daily production status through the data statistics report in the system backend. The platform has enabled the input, real-time query, and statistical analysis of production data for various production positions. The system provides a production data integration platform for enterprises, truly realizing information communication and instant sharing between offices and production sites.

Quality Assurance

| formerly | The Quality Department currently documents product defect occurrences on-site using paper-based records, then relays the information to relevant personnel for production process adjustments. This manual feedback loop results in operational inefficiencies, with significant delays in identifying and resolving quality issues effectively. |

| now | The quality department can quickly record product defect information online, making product quality monitoring organized |

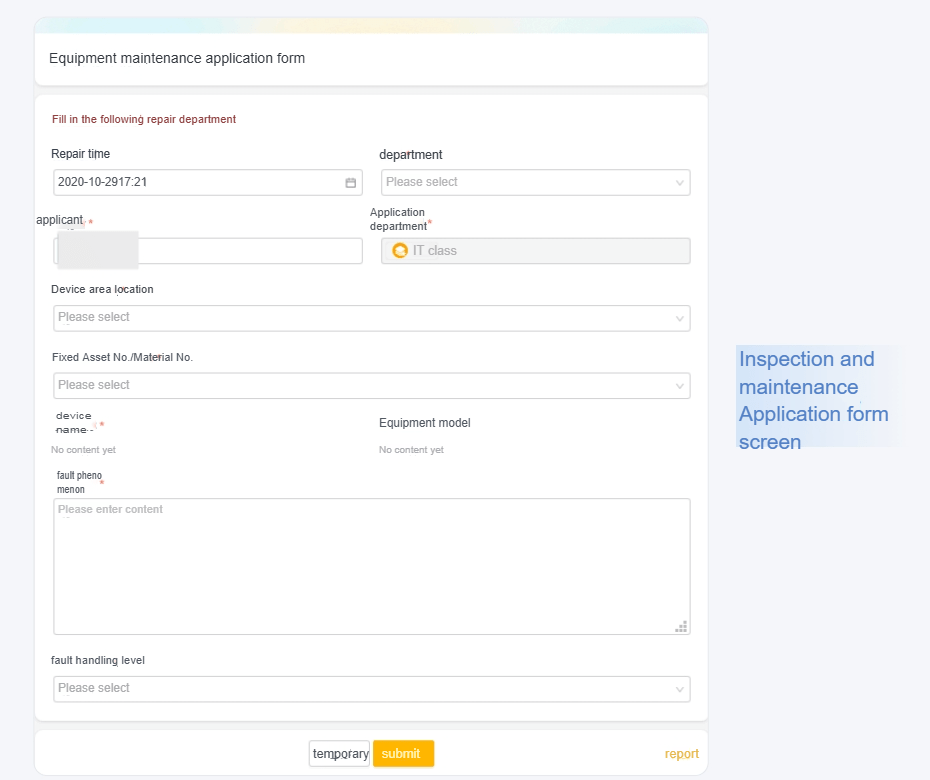

Equipment inspection

The company has deployed an Equipment Inspection Management System to digitally manage routine inspections and detailed equipment checks. During inspections, when operational issues are identified, maintenance staff can instantly capture and upload photographic evidence through the system. The platform automatically routes these alerts to designated maintenance personnel while simultaneously triggering real-time SMS alerts and email notifications to ensure prompt resolution.

Material inventory

For manufacturing enterprises, production departments require real-time visibility into the precise locations and remaining quantities of production materials to facilitate immediate access and requisition during operations. The implementation of an integrated inventory management system enables production teams to monitor raw material specifics and storage positions with accuracy. By establishing a comprehensive production and material control framework, the company ensures systematic coordination between manufacturing processes and material flows.The modular enterprise management platform empowers operational staff to customize systems tailored to specific needs—such as equipment inspection, production monitoring, and EHS (Environment, Health & Safety) management—through no-code/low-code configurations. This technological transformation replaces traditional inefficient manufacturing practices, propelling the organization into an era of digital lean production.