Company background

This is a professional equipment component manufacturing enterprise engaged in forging and heat treatment, with products widely used in energy fields such as petroleum, natural gas, deep-sea, wind power, chemical, mining machinery, and ships.

Facing challenges

- Transparent management: As a manufacturing enterprise, the operation process of the production workshop cannot achieve transparent management. Managers need to personally get off the workshop to understand the overall production situation, which undoubtedly increases the difficulty and cost of management.

- Data statistics: Currently, production process data is manually collected by workers, which is not only inefficient but also prone to errors, which is not conducive to data analysis and optimization.

- System Applicability: The enterprise once purchased a set of vertical industry SaaS, but found that the inherent modules of the system did not match the actual situation of the enterprise, and the customized functional modules could not be implemented, which caused great difficulties for the enterprise in practical operation.

Enterprises urgently need to address how to improve efficiency and accuracy in production management, data statistics, and system usage to meet the needs of actual production and management.

Effect value

1.Process Management of Fine Chemical Plant Workshops

Starting from the source of materials, control is implemented to ensure that managers strictly control key production nodes and eliminate issues such as raw material waste.

2.Sort out and standardize business processes

In the past, there was no strict standard process for the entire production process. After using the system, the manager reorganized the business logic to ensure that the process was simple and efficient, and the data was traceable.

Core application scenarios

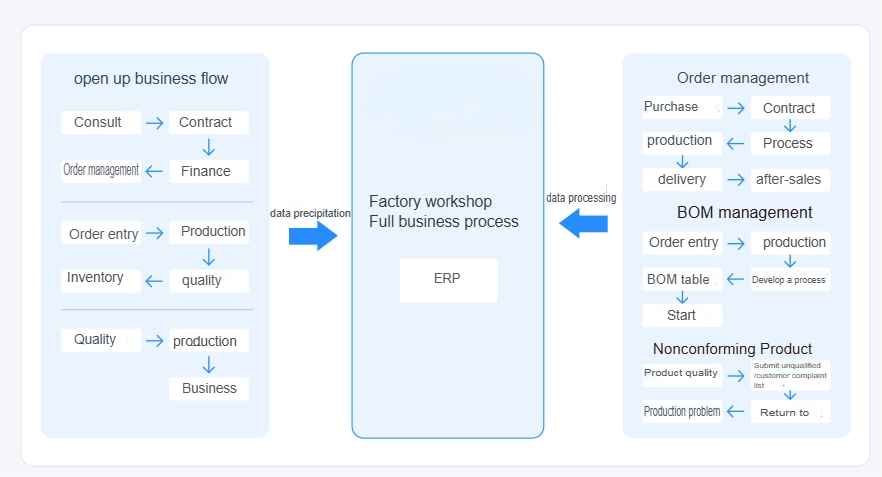

ERP application

In the actual use process, it has helped the enterprise forge the collection of key data, resource integration and utilization from purchase order entry → contract approval → process design → production → shipment → after-sales, achieving closed-loop management of the entire business process.

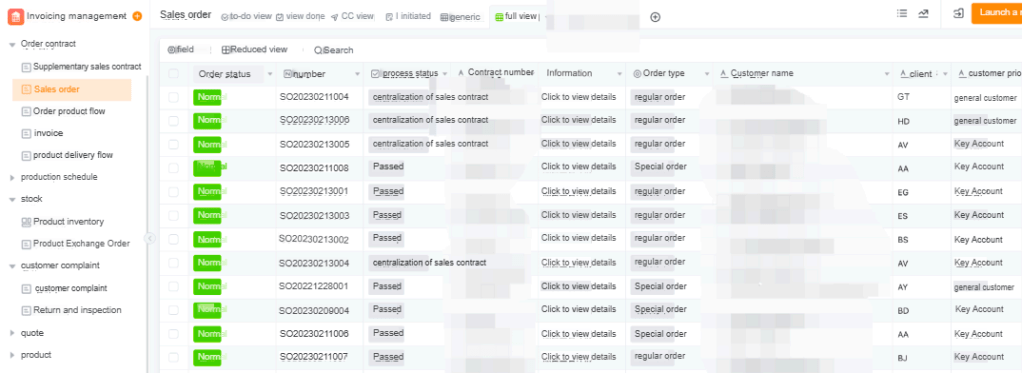

Order management

Taking the order process as an example, when sales personnel receive an order, they enter the contract into the system. Before the contract officially takes effect, it needs to be approved by relevant personnel in each department, and the system will automatically flow to each approver. After the contract is approved, sales personnel can stamp and return it, and the contract will be centralized to achieve closed-loop management of the entire order management process.

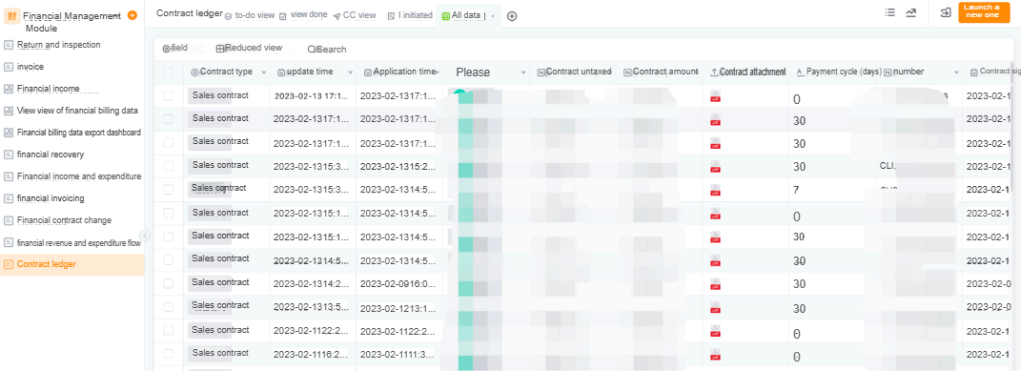

Contract management

All approved contracts will ultimately be centralized to the finance department, which will carry out corresponding financial operations on the performance of the contracts to ensure that all contracts can be processed in a closed loop.

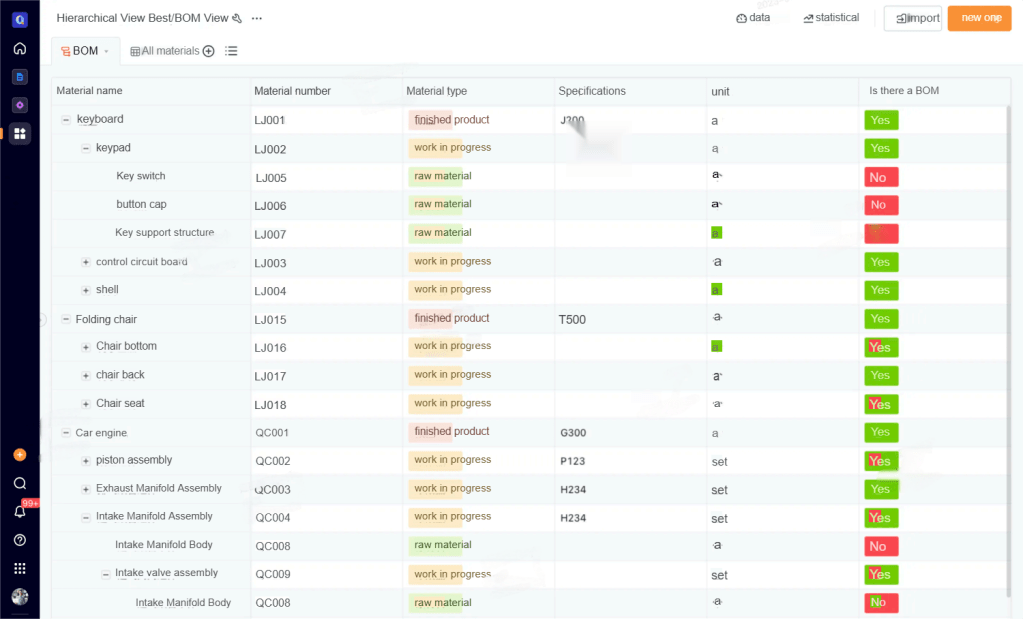

BOM Management

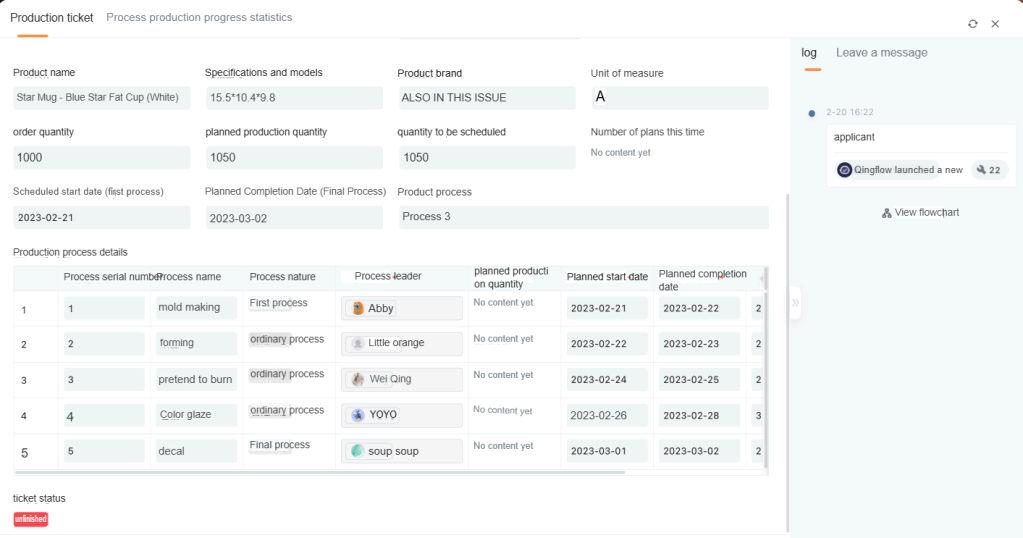

After the order is entered into the production process, the technical department will develop processes and procedures based on each product requirement. Each product will have a corresponding BOM table, which will be recorded in the system. The production department will start production after receiving the BOM table online. The production process is standardized here to ensure that each process of the product is completed according to the process requirements, and there are corresponding acceptance requirements in each process. Production and inspection personnel strictly follow the process requirements to ensure the stability of product quality.

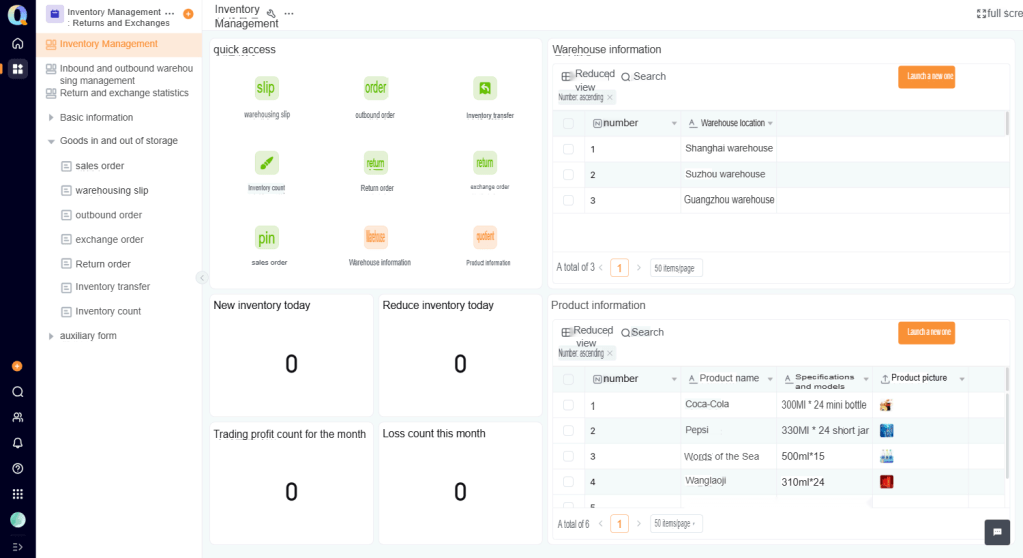

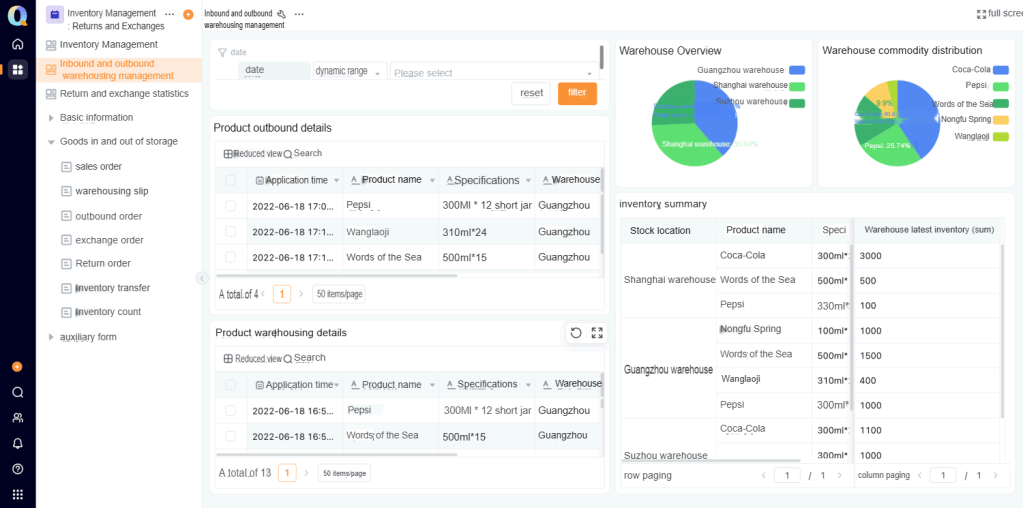

Inventory management

After the production of the product is completed, the system will automatically initiate a reminder to enter the warehouse, and warehouse personnel can confirm the product upon receiving the system’s to-do list.

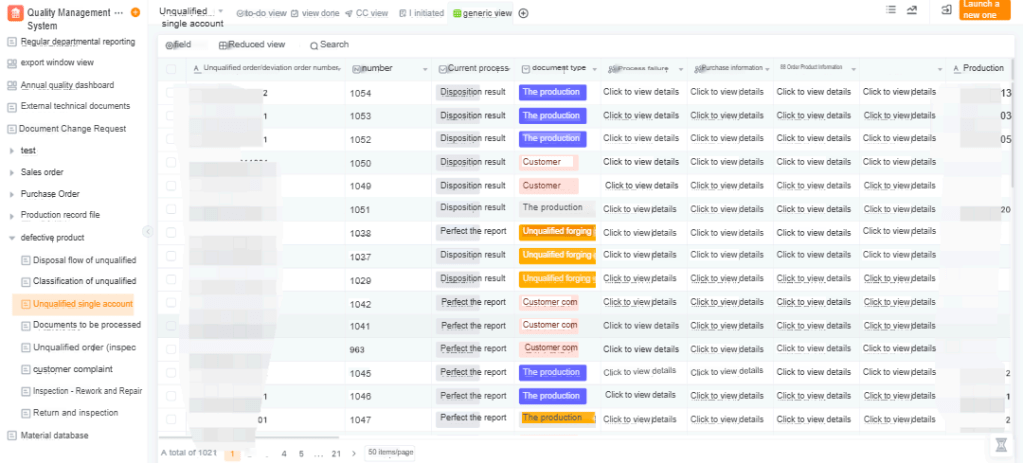

Non conforming product management

At the same time, the quality department will also complete product quality inspections based on the inspection standards and processes in the system. If any non-conforming products are produced, business personnel will directly submit the non-conforming product list/customer complaint form online, and the products will be returned to the production line. As the entire production process is recorded on the light flow, production problems can be traced and the specific link where the problem occurred can be quickly identified.